CoilMaster

Twin condensing boiler with high hot water output

CoilMaster

Twin condensing boiler with high hot water output

Modern living demands energy efficient boilers and enhanced building insulation has shifted the main requirement of gas consumption from heating to hot water, and in many cases the demands of the hot water service exceed that of heating. Therefore it is important to install an appliance that condenses in both heating and hot water mode, achieving the most from every kW input of gas used.

NOx class:

Modulation ratio up to:

PERFORMANCE

| heat input (net) G20/G25 | kW | 9,5 - 57,5 |

| heat output at 80/60°C G20 | kW | 9,2 - 55,9 |

| heat output at 50/30°C G20 | kW | 10,3 - 61,6 |

EFFICIENCY

| heating efficiency 80/60°C | % | 97,1 - 97,3 |

| heating efficiency 50/30°C | % | 108,2 - 107,2 |

| useful efficiency at 30% (return 30°C) | % | 108,2 |

| seasonal efficiency | % | 92,4 |

GENERAL

| seasonal space heating energy efficiency class | A | |

| water heating efficiency class | A | |

| gas categories | I2E(S), I2E, I2Er, I2H, I3P, II2E3P, II2EK3P, II2ELL3P, II2Esi3P, II2H3P, II2L3P | |

| gas types | G20 - G25 - G25.3 - G31 | |

| chimney types | B23 - B23p - C13 - C33 - C43 - C53 - C63 - C83 - C93 | |

| primary water content | l | 63 |

| domestic hot water content | l | 18 |

| CO emission | mg/kWh | 43,3 |

| NOx class | 6 | |

| max DHW operating temperature | °C | 80 |

| max operating pressure heating (primary) | bar | 3 |

| max operating pressure (DHW) | bar | 8 |

| voltage | V | 230 |

DOMESTIC HOT WATER PERFORMANCE

| 1st hour and continuous hour at 40°C | I/min | 27,2 |

| 1st hour and continuous hour at 60°C | I/min | 16,3 |

| water heating efficiency | % | 104 |

| load profile for water heating | XXL |

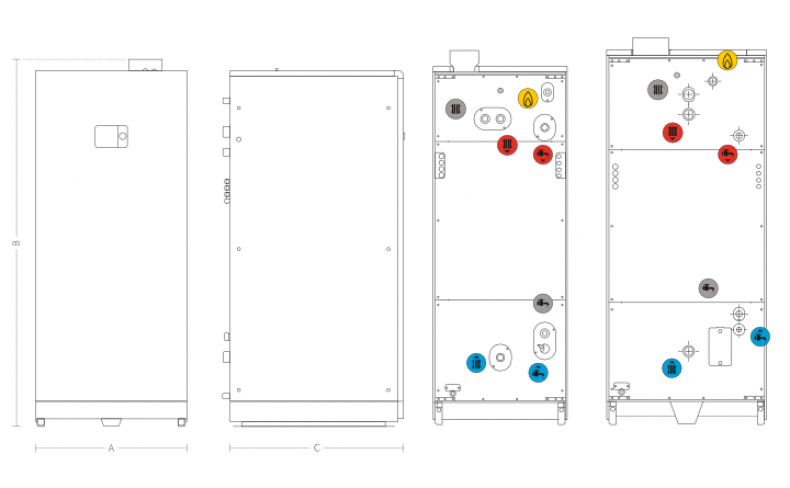

DIMENSIONS

| boiler width [A] | mm | 632 |

| boiler height [B] | mm | 1446 |

| boiler depth [C] | mm | 774 |

| dry weight | kg | 200 |

CONNECTIONS

| chimney connection | mm | 100/150 |

| gas connection | in | 3/4 |

| pressure relief valve connection primary side | in | 1 1/4 |

| pressure relief valve connection DHW side | in | 1 |

| DHW outlet | in | 1 |

| primary circuit outlet | in | 1 1/2 |

| DHW inlet | in | 1 |

| primary circuit inlet | in | 1 1/2 |

ERP Labels (1)

Current technical manuals (7)

| CoilMaster 60-120 (EN) | |

| CoilMaster 60-120 - gas conversion | |

| CoilMaster 60-120 | |

| Webserver | |

| Controls - Controller Manual - NC, CM, TX,TMU | |

| Controls - OCI Clip in Manual | |

| Controls - AGU Technical Manual |

Schematics (1)

Sales Brochures (1)

BIM (1)

Certificates (2)

Key Features & Benefits

- High DHW production 3.270 l/h

- Useful efficiency in DHW mode 104%

- Internal circuit piping in welded stainless steel

- Coil Fire Tube heat exchanger in stainless steel

- Self-cleaning flue ways, anti-legionella

- Low pressure drop

- Low NOx

- Compact dimensions